Well Failure Analysis (Added May 2013)

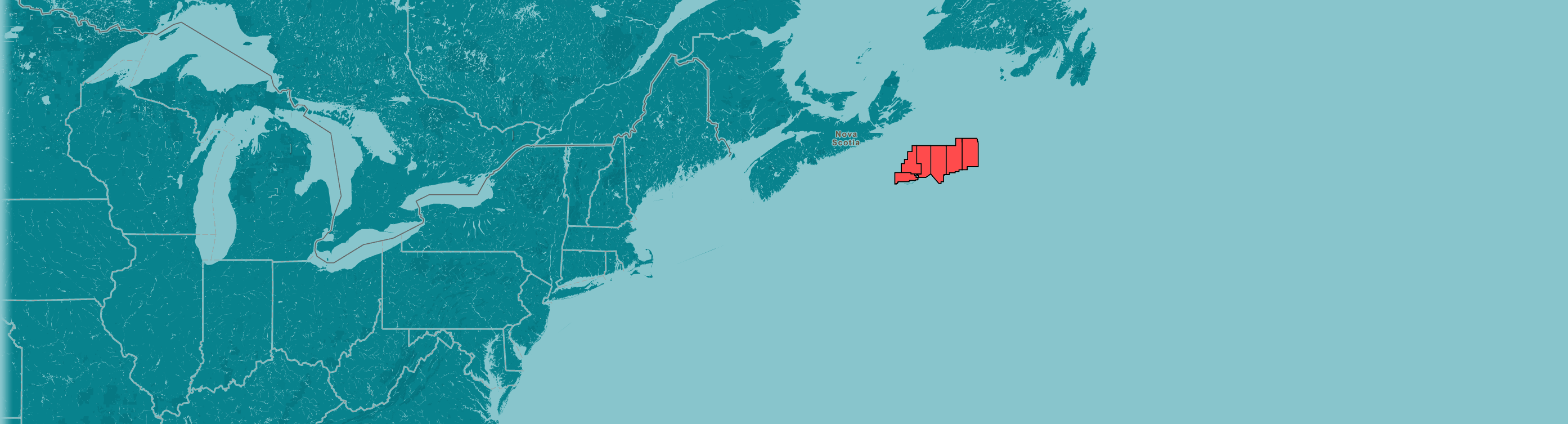

NS13-1 Hydrocarbon Wells - Well Failure Analysis

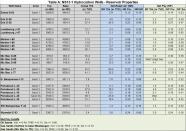

In May 2013, the CNSOPB completed a petrophysical evaluation and well failure analysis of the ten wells in the NS13-1 Call for Bids that encountered hydrocarbon bearing reservoirs. The results of this petrophysical evaluation appear in Table A.

As described in the NS13-1 Call for Bids Source Rock and Maturation section, marine strata in the early Jurassic (Pleinsbachian to Toarcian) and the late Jurassic (Tithonian) are interpreted to be the primary source rock intervals in this region of the Scotian Shelf. The Tithonian source rock is believed to have generated significant volumes of both oil and gas while the Pleinsbachian to Toarcian source rock is interpreted to have generated mainly oil. Given the interpreted regional extent, generating capacity and the significant number of wells (10) that encountered hydrocarbon bearing reservoirs, inadequate source is not considered to be a primary well failure mechanism. As a result, the CNSOPB’s well failure analysis focussed on reservoir presence, reservoir quality and seal as the most likely well failure mechanisms.

Reservoir presence was described using the ratio of net porous sand thickness to gross thickness (net/gross). Where sands were encountered, reservoir quality was determined from the average porosity of these intervals. In order to evaluate seal effectiveness, time and/or depth structure maps at or near the hydrocarbon zones were created. These maps were used to develop an understanding of the hydrocarbon trap and the potential spill points.

In many of the ten NS13-1 hydrocarbon bearing wells, the net/gross in the Missisauga Formation is either high or very high and the sands have good porosity. Therefore, fault dependent traps are generally ineffective and the hydrocarbon bearing sands are trapped within simple closure. In general, this lack of fault seal, in the Missisauga, limits hydrocarbon column heights as the accumulations are limited to the extent of 4-way dip closure. Where the Mic Mac has net/gross values that are fair to high and porosity that is fair to good, fault seal is also ineffective. In wells where the net/gross and porosity values, of the Missisauga and Mic Mac Formations, are fair or better the lack of fault seal is the main well failure mechanism.

In the Mariner I-85 and Louisbourg J-47 wells, the Mic Mac Formation has low net/gross, low porosity and a number of interbedded tight limestones intervals. These factors allow faults at this level to seal which results in greater hydrocarbon column heights. However, in Mariner and Louisbourg, the Mic Mac sands have poor reservoir quality as they are relatively thin with gross thicknesses from 8 to 20 metres and also have low net pay thicknesses (1–5m) and low porosities (8–10%). Although gas bearing sands were encountered in these wells, lack of reservoir in the Mic Mac Formation is the main well failure mechanism. The results of the CNSOPB’s well failure analysis for the ten NS13-1 hydrocarbon bearing wells are summarized by pre-spud target formation(s) in Table B.